Complacency – the Enemy of Quality

by Mark R. Hagen

Three companies carry on improvement initiatives while business is booming

Over the years quality has scored its biggest successes—and gained the most attention—when business was bad. The Japanese turned to U.S. quality experts to help rebuild their economy after World War II. The U.S. automotive industry borrowed those “foreign” ideas in the 1970s and 1980s to regain market share. In an often told story, Texas Nameplate Co., one of last year’s Malcolm Baldrige National Quality Award winners, started its intensive improvement efforts only after one of its biggest customers threatened to cut Nameplate off if it didn’t get serious about quality.

The reverse of this equation, unfortunately, is that enterprises sometimes forget the value of quality when things are going well, when they are enjoying double digit sales increases, year after year of record breaking volumes or an unquenchable demand for their product.

With October being National Quality Month, the American Society for Quality considered three companies—a staffing services firm, a winery and a mortgage lender—that haven’t forgotten the importance of quality even while riding the crest of strong demand. ASQ and Quality Progress met with the quality experts behind these companies to discuss the need for continuous improvement—particularly when business is booming.

As Joseph P. Goryeb, founder and CEO of Champion Mortgage—one of the three featured companies—says, “Any company that thinks it’s doing great and doesn’t need to improve any further, is going to be passed by. Any time you think you’ve done it all, you’re not going to make it.”

Manpower

The leader of its pack

Manpower Inc. is a staffing services firm that has almost done it all, yet shows no sign of slowing its improvement initiatives.

The staffing service industry doesn’t usually come to mind when one considers big businesses. This industry, however, increased its profits more than $38 billion in the last eight years and reported $58.6 billion in sales for 1998—its seventh consecutive year of double digit growth (16.6%).1 At the top of the industry sits Manpower Inc., headquartered in Milwaukee. Manpower currently manages 3,200 offices in 52 countries making it a global leader among employment services. Manpower’s systemwide sales have increased every year since 1991 and in 1993, despite roughly $4.1 billion in systemwide sales, it embarked on a massive quality initiative. Similar to that experienced by Texas Nameplate, Manpower began to feel pressure to formalize its quality program endeavors.

Taking on ISO

As the ISO 9000 quality standards began to grow in acceptance, several European companies required that suppliers adopt the standards. “I don’t think our customers realized they were including service companies as well as manufacturers at the time they made that demand,” says Melanie Cosgrove Holmes, Manpower’s senior vice president and quality officer. “But if Manpower wanted to do business with European companies it had to register to ISO 9000.”

ISO 9000 registration seemed an odd venture for the service organization. At the time, Manpower registered more sales than it had in years and was already considered a leader in its industry. The standard itself was manufacturing oriented and seemed difficult to apply. As Manpower went through the process, however, it increasingly realized the importance of quality improvement—even in good times.

Holmes says, “We wanted a way to ensure that all of our offices were following a standard system and to prove to our customers that we did, indeed, have seamless offices throughout the world.”

Manpower’s headquarters office pursued registration and in 1994, less than a year after beginning the process, the company became one of the first global service companies to register to ISO 9002. (For information on how Manpower adapted the ISO 9000 standards, refer to the sidebar Applying ISO 9000 to the Service Industry.)

Manpower consistently invests in tools for employee training, such as its Quality at Work video training series used by more than two million employees.

Selling Quality to Upper Management

Present how the project can alleviate other costs in the organization. When you have a good quality program, your customers are more satisfied so the company experiences better customer retention. Employee retention also increases because employees are not as frustrated by the rework they had to do before the project was initiated.

Explain where else this has been done and what effects it had on the organization. Directly question a similar company on the benefits and disadvantages of the project. Use this data to explain what the competition and the best in class is doing. Make the presentation relevant to your particular industry and your competition.

JEFFREY A. JOERRES

PRESIDENT AND CEO

MANPOWER INC.

The way to get buy-in from management is to get them involved in your idea. You do this by sitting down with management individually, telling them what you’re thinking about initiating and why you think its good for the company.

Ask for their views and suggestions. Ask how they think it will affect the company. One-on-one communication not only gets you support, but it helps develop the idea. It also identifies who is opposed to your idea and helps you understand the reasons for their opposition. You can then work on addressing these concerns and getting support from these people.

MARJORIE TRAUTMAN

DIRECTOR OF SERVICE QUALITY AND ORGANIZATIONAL DEVELOPMENT

CHAMPION MORTGAGE CO., INC.

Do your homework and think through the total effect of the investment you are suggesting. Know all of the costs involved, what it can do to improve quality and how it can improve profitability. Include how much you think the quality project will save: Is it a two-year payback? A four-year payback? In doing so, the decision becomes more concrete.

A good idea on its own may or may not work in an industrial situation. A good idea coupled with a precise definition of dollars and cents, however, works in that it helps build a strong case.

SU HUA NEWTON

CO-OWNER NEWTON VINEYARDS

The Predictable Performance System

Manpower’s success is largely due to a system it had been using since the mid ‘70s. “Our Predictable Performance System is our quality system,” says Holmes. “ISO 9000 is the affirmation that the system follows sound quality management system principles.”

The system uses a combination of interviewing, testing and training to predict an employee’s performance success before he or she is sent on an assignment. Manpower president and CEO Jeffrey A. Joerres believes ISO 9000 registration was a way to “put a badge on (the system), verifying that it was indeed a quality process.”

The CEO adds that Manpower uses “ISO 9002 to evaluate the process to insure that it is predictive of quality. If it is, then our quality measurements should go up and they have.”

Holmes agrees, “Our success rate continues to improve since our quality programs have been in place. Currently over 40% of our contract employees transition into permanent work at our customers’ companies.”

A changing industry means continuous improvement

“After becoming registered, you have to move to the next level,” Joerres says. “The next level is maintaining and continuing to evolve what’s in your ISO 9000 manual. You can’t let it just sit there because your business doesn’t stay still.”

And the staffing business is certainly not one to stay still. As new staffing requirements fuel the need for highly skilled employees, business is turning to temporary staffing services to provide workers who can best accomplish necessary tasks.2

Today, companies are retaining staffing firms to provide several human resource services such as recruiting, skills training, risk management and payroll benefits administration.3 “We’re seeing a much more strategic use of our services. As a result, it’s important for Manpower to take advantage of quality concepts that address those strategic applications,” explains Joerres.

While Manpower’s global operations seem the stuff of legends, the company continues to expand its quality endeavors and relies on several tactics to meet changes in its industry. The keys to Manpower’s quality endeavors center on:

- The ISO 9000 manual. Joerres believes the quality manual must be kept applicable to the direction in which the industry is headed. “If you don’t continuously update your manual,” he says, “your quality standards will not be in line with what your customers are looking for.”

- Feedback. The Quality Performance Program is the feedback program Manpower created to determine changes in customer needs, measure the Predictable Performance System’s success and gauge employee satisfaction. The feedback is obtained through weekly calls and quarterly written surveys.

- Training and development. Manpower’s internal customers—front-line employees sent to work at customer companies—are constantly trained to meet changing customer requirements. “It’s our contract employees who control Manpower’s quality reputation; therefore, we face a tremendous challenge to continuously help those people realize how important they are to us and our reputation,” says Holmes. “We strive to help them get ahead through developing their skills and offering constant feedback.”

Maintaining best of class

Manpower’s efforts are paying off in a big way. Despite the costs involved in keeping abreast of technical innovation, changes in foriegn tax legislation, and industry related mergers and acquisitions, the company reported a one year systemwide sales growth of 21% for the last fiscal year.

Currently, more than 2,475 Manpower offices are registered to ISO 9000 or equivalent foreign standards, and the company continues its efforts to register its remaining offices.

Newton Vineyard

Cultivating pride

Developing employees and helping them become enthusiastic about the quality of the final product is a necessity to Su Hua Newton, co-owner of Newton Vineyard in Napa Valley, CA. “When employees feel pride in their work,” she says, “you know they share your passion for excellence.”

Newton established her first vineyard in 1972, becoming one of 26 wineries in Napa Valley and its surrounding regions. Four years later, Napa Valley wines won top honors at an international wine tasting and flooded the California wine business with foreign investors.4 Today, more than 840 wineries occupy California.

As competition among wineries intensified, vintners began reassessing their winemaking techniques, making quality a catch-phrase throughout California’s wine country.5 Newton says that quality remains the key to survival in a business that continues to attract new competitors. “If you have outstanding quality,” she explains, “people will beat a path to your door.”

Luc Morlet, Newton Vineyard’s director of oenology (right), believes its important that employees partake in wine tastings to compare the final product against the competition.

Working quality from ground zero

Newton believes that no matter how successful a company becomes, it must continuously practice quality from the beginning to the end of every process. “Quality must start from ground zero, such as the vine and the barrel,” she says. “Nobody sees these things, but by the time the wine gets to the bottle, it’s too late to make adjustments for quality.”

Implementing quality from the start means having employees who understand the level of excellence that must be met at every stage of a process. Newton believes this can be accomplished by encouraging an emotional link between the employee and his or her responsibilities. “If employees are emotionally involved with their work, they will invest the effort to pursue excellence.” This enthusiasm is nurtured through the way work is assigned at Newton Vineyard.

The vineyard is divided into sections. Workers are then assigned to a section for which they are held accountable. “One person is in charge of the Merlot area, one person is in charge of Cabernet and so on,” Newton explains. “The land is mine on paper, but I tell the workers that the area assigned to them is theirs. They get emotionally involved because they take ownership of it.”

Once the vines begin to produce, Newton regularly takes three to four workers for drives around the valley. Practicing an informal type of benchmarking, Newton and her workers stop at other vineyards, tasting grapes so employees see how the produce they cultivated compares to the competition.

Newton believes the employees feel proud of their work because they see the results of their efforts. “They see the difference of their efforts in the land every day, every year. It’s important they recognize the result of their own work.”

Educating front-line workers

Newton often eats lunch with vineyard staff, where she facilitates discussions about “the raw material used to make the food and how it relates to the overall production process.”

Similarly, she holds regular wine tastings with staff, at times inviting international wine experts to critique the wines and discuss wine making. “Any expert has some information, input or view to offer,” Newton says. “The frontline workers should be exposed to this insight.”

“It’s important to have a point of view from someone outside the company,” agrees Luc Morlet, Newton Vineyard’s director of oenology. “It’s important to have a basic critique of the product and get criticisms from other countries. It makes us re-examine our processes.”

“If you have people who really care about what they do and desire to learn about the product, you know they are emotionally attached,” Newton adds. “You know they are proud of their work and share your passion for the quality of your final product.”

Newton believes this passion—to learn as much about a product and the industry as a whole—will keep any organization abreast of change and help it stay on the cutting edge in good times and bad.

Applying ISO 9000 To the Service Industry

When Manpower Inc. decided to register to ISO 9000, the service organization entered largely untraveled territory. Manpower’s senior vice president and quality officer Melanie Cosgrove Holmes and president and CEO Jeffrey A. Joerres offer a few methods to help service industries use the ISO 9000 standards.

Clearly define the product. “In order to succeed with ISO 9002, you need to clearly define what your product is and understand exactly what you’re providing to customers,” says Holmes. “Once we defined the product, it was much easier to apply the standard.”

After considering its options, Manpower defined its end product as the match it makes between its client company and the temporary employee. “Our end product is not that dissimilar to that of a manufacturer,” explains Joerres. “When we put the best matched person in a customer company based on our quality system, that company sees an increase in productivity. Like manufacturing, great quality gives better productivity and better reliability.

Relate your processes to manufacturing. “There is a manufacturing process to anything you do and I think that’s key to understanding how you apply ISO 9002 to a service business,” suggests Holmes. “Manpower’s raw materials come in the form of the people and the skills they have to offer. We take that material, test it and improve it.”

Holmes says the same holds true of the requirements customers demand of Manpower. “At Manpower, customer requirements don’t come on blueprints with specifications such as density, weight, calibration and all of the things you’d find when dealing with ISO 9000. We continuously communicate with our customers to see what their needs are or if their needs have changed.”

Update your ISO 9000 manual. Once becoming registered it’s important that service organizations continuously update their ISO manuals. “Maintaining it has to be relevant to where your business is going,” says Joerres. “You have to look at your processes and decide how they need to change to be the most contemporary quality standards for your customer.”

Champion Mortgage

Saying yes to customers and quality

“Any company that thinks it can sit back on its haunches because it’s doing wonderfully and business is great is headed in the wrong direction,” says Champion Mortgage Co., Inc. founder and CEO Joseph P. Goryeb. “We decided we wanted to stay in front of the pack, which is why we created and continue our quality program.”

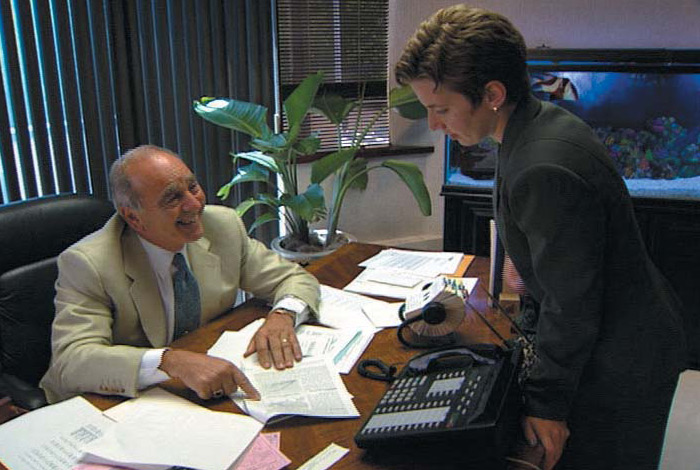

Joseph P. Goryeb, (seated) founder and CEO of Champion Mortgage Co., Inc., says it’s imperative to train and develop employees so they can best meet the demands of customers, grow with the company and meet changes taking place in the industry as a whole.

After establishing Champion’s two-employee office in 1981, Goryeb expanded the company to 27 branches with almost 750 employees. In 1989, Champion began what would be a three-year run on Inc. magazine’s list of fastest growing companies.

“As the company experienced its rapid growth, there was a concern from senior management that we’d lose the personal touch we had with customers,” says Marjorie Trautman, Champion’s director of service quality and organizational development.

By 1992, Champion (now headquartered in Parsippany, NJ) was averaging $1 million per year in business. “We were breaking records, our bottom line was wonderful and we were doing phenomenally well, but we decided to formalize a program to make us the best company we could possibly be,” Goryeb says.

“We wanted a vehicle that would allow us to share our values with the organization as we grew,” adds Joseph M. Goryeb, Champion’s co-president, COO and Joseph P. Goryeb’s eldest son. “We didn’t want to grow in a way that was uncomfortable for us or grow just for the sake of numbers and profits. This is how we got involved in a full-fledged quality initiative.”

Champion’s Service Quality Initiative

The Service Quality Initiative (SQI) is Champion’s total quality management program involving any processes or factors affecting customer satisfaction. Trautman says the program ensures consistent quality service throughout its branches and trains new employees in Champion’s culture, allowing the culture to grow at the same rate as the company.

The quality system consists of several factors: a reward and recognition program aligned to drive desired employee behaviors; a communication strategy created to encourage front-line workers to voice their opinions and keep all employees involved in decision making; service quality teams assembled to address internal and external customer issues and streamline processes; and training endeavors designed to foster employee development.

As the business and industry grew, so did the quality program. When the program began in 1992, nearly all of the training was conducted by management. Now front-line employees and other staff spend 5% of their time facilitating sessions once every other month.

The same can be said of the service quality teams structured to drive change. Currently, 75% to 80% of Champion’s employees participate on a service team at any one time.

Not only did the SQI help Champion improve its already successful service practices, it also propelled the mortgage company to leadership status in the lending business. In 1998 the company added 200 new employees, increasing its staff by 45% in a single year. Champion’s 1998 business volume totaled $922 million (a 59% increase over the previous year) and is on track to lend $1.2 billion this year.

“A quality service system is not only the right thing to do from a service quality point-of-view,” says COO Goryeb, “it’s the right thing to do from a bottom-line profit point-of-view.”

Involving employees and vendors

Champion’s pursuit for excellence never stops; the company continues to address culture, staff and customer service issues.

To ensure service is consistent throughout the loan process, for example, the company extended the SQI to its vendors—settlement agencies, and title and appraisal companies. “We work hard to keep the customer our number one priority and to provide the service our reputation is based on,” says Trautman. “It’s extremely important our vendors understand our culture and expectations.”

Champion offers vendors the same service quality training Champion employees receive. The lender also practices a cross-training initiative in which Champion employees visit vendors to understand how the two companies interact. According to Trautman, the interaction “helps the employee see how his or her actions affect the vendor and vice versa. It builds a tighter relationship and creates opportunities to improve how the employee and the vendor work together.”

Measuring performance

Customers who complete the loan process are surveyed regarding their satisfaction and future expectations. “We also survey those customers who dropped out of our process to find out why they choose not to do business with us,” the COO explains. Champion relies on a quarterly summary of measurements— a customer service index—including data collected from telephone surveys, written surveys and focus groups.

Champion’s COO says, “The most important question we ask customers is if they’d do business with us again or if they’d refer friends and family to us.” According to a recent customer satisfaction index, 98% of Champion’s customers say they would return their business to Champion and recommend the company to others.

Champion also measures its internal processes. Each month a random sample of staff is asked to take part in an employee satisfaction survey; all employees partake in a year-end satisfaction survey. “There’s no magic to providing service excellence,” COO Goryeb believes. “If you have happy motivated employees who feel they can make a difference to the organization, they’re naturally going to provide the kind of customer service you’d expect.”

Improvement is key

Champion believes the way it handles its customers is what keeps it ahead of the competition. The COO says the company is constantly looking at its processes and procedures from the customer’s viewpoint and investigating every interaction the customer has with Champion. He warns that it’s important to look at internal processes and weigh them to be sure they are designed for the customer and not internal convenience.

“When things get easy is usually when the competition catches up,” says Trautman. “We know that if we are continually working to improve the things we do—through our process improvements and by evaluating customer needs—we are always going to be many steps ahead of the competition.”

Staying on the right track—for good

Similar messages became apparent as the quality practitioners discussed their keys to success. All three companies used employee development to meet the needs of future customer demands, improve staff satisfaction and enhance a positive work environment. The companies also identified the need to address quality concepts on an ongoing basis and consistently revise processes to meet changes in industry.

Will Rogers once said, “Even if you’re on the right track, you’ll get run over if you just sit there.” Most quality experts would agree. While the temptation to neglect quality in favor of quick profit can be great, a lack of continuous improvement will even leave the leader of the pack in the dust.

REFERENCES

- Timothy W. Brogan, “Staffing Services Annual Update,” a report for The National Association of Temporary and Staffing Services, Alexandria, VA, 1999.

- The National Association of Temporary and Staffing Services, “Industry Information,” www.natss.org.

- Edward Lenz, “Flexible Employment: Positive Work Strategies for the 21st Century,” Journal of Labor Research, 1996, see www.natss.org/flex.txt.

- “History of Wine Country,” http://http2.smartpages.com.

- “The History of Wine,” www.wineeducation.com.

BIBLIOGRAPHY

- Burr, Michael, “Permanent Temps,” Government Executive Magazine, March 1997, www.govexec.com/features/0397s5.htm.

- Holstein, William J., “Are Raises Bad for America?,” U.S. News and World Report, Vol. 127, No. 8, 1999.

- Larson, Jay, “Temps are Here to Stay,” American Demographics, February 1996.

- Lewis, Shawn D., and Tom Greenwood, “The Changing Workforce: Temp Jobs Bridge Welfare and Work,” The Detroit News, July 22, 1997.

- Studer, Margaret and Gabriella Stern, “Swiss Temp. Firm Shoots to No. 1 Spot in U.S.,” The Wall Street Journal, Aug. 19, 1999.